“Stop it Doing” was the original headline. This was a tribute to my nephew when he was learning to talk. Since I am in the same boat (hehe), why don’t you “stop it doing” the following things:

Like learning versus unlearning; at some points in your Deming journey, it is equally important to STOP doing certain things: Let’s say,

If you were lost in the woods and just realized you were headed in the wrong direction, what is the first thing you would do? Ideally, before hauling ass in the opposite direction, you would STOP. Pause. Assess. Reevaluate. (PDSA?)

Where do you begin undertaking the Deming approach?

Anywhere.

Just be sure to communicate what you are trying to accomplish, why and how. This drives out fear by letting people know how you intend to operate the organization.

You can eliminate incentive pay

It causes people to cheat, cut corners and ignore anything except achieving the incentive being dangled out in front of them.

You can move your sales force from commission pay to salary and profit sharing – so they can cooperate when sales for the organization rather than compete with one another to win a bonus.

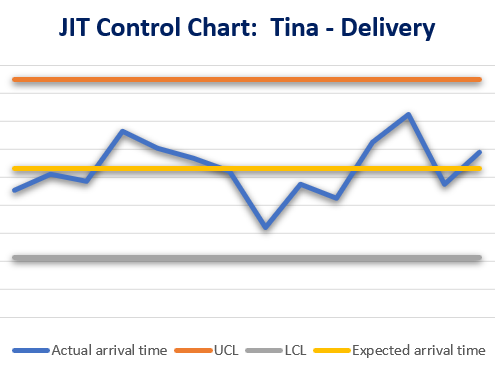

You can start to use control charts to examine data for special causes versus common causes of variation. That alone will save you an incredible amount of money and time. You can use Doctor Deming’s methods to conduct an assessment, a performance appraisal of the system. In which the people work because as Deming pointed out some 94-98% of the results come from the system in which people work. (Disregard the poor color scheme.)

You can stop managing by visible figures alone.

Instead of relying on the visible figures on spreadsheets, learn about what is causing the numbers to be what they are.

Rather than trust the visible numbers, put the data on control charts. This will tell us whether to improve one specific aspect of the process right away (because it is likely a special cause), or whether we should continue working on improving the process overall (because the chart shows a common cause situation).

Furthermore, spreadsheets cannot predict the future. Control charts are much better for making predictions. In fact, a control chart will provide you with the view as to whether or not it makes sense to try to predict future results. If the capability of your system is unstable, it is a bit dangerous to try to predict a stable future.

You can Stop Tampering.

Tampering, for example, is when you ask for a specific reason why a result is different from a previous result, such as why were there more errors this week than last week?

When you asked for the reason why results were better or worse last week. You are unintentionally encouraging people to give you a specific reason. If you accept this and go no further, you could be overlooking serious common cause influences on the results.

Research indicates that the human brain tends to default to an assumption that there is a single, specific and often readily observable reason why results vary. This means that we are assuming outcomes are the result of a special cause. And we overlook the common causes of variation.

Special cause variation would be something we can see.

Common cause variation would be the sum total of all the inputs that caused the outcome to be what it is. Within any process you can expect to see variation: The results will fluctuate. They will vary. There is natural variation.

It does not make sense from a time, money or resource standpoint to try to pinpoint a specific cause of variation when the control chart indicates that the variation of results is within the range of expected results.

The way to identify common cause variation versus special cause variation is to use a control chart to plot the data. It is counterproductive to speculate, especially when a control chart would have made it clear whether the variation week to week was within the range of predicted by the controlled chart or not.

Mistaking one cause of variation for the other, can hurt the system. See funnel experiment.

You can stop asking people to provide their best efforts.

This does not contribute to improving the processes and systems in which people work.

Workers tend to realize this more than managers because workers find themselves constrained by policies and procedures that do not make sense, or are contradictory, inadequate or confusing.

Worse still, workers trapped by inadequate processes or systems tend to become demotivated.

If you want to bring out the best efforts in your workers, help them be successful and in improving quality. Instead of by exhorting them to work harder or by trying to motivate them with posters and pep rallies.

You can stop fostering internal competition between people and departments.

Instead, focus on fostering intense cooperation to improve quality.

Forcing people into departments to compete for prizes or recognition will destroy teamwork and cooperation. This is a surefire way to destroy your organization.

If you want to increase efficiency and effectiveness, if you want to increase competitive advantage, make sure the people in your organization are working together to optimize the overall organization rather than causing them to focus on improving their own area.

You can stop being seduced by “best practices.”

Best practices are seductive because when we see an organization that is winning with products or services, our natural childlike reaction is to copy what that organization is doing.

We tend to believe that best practices solve systemic issues, and they might. However, piling one back best practice on top of another seldom makes sense.

The result of organizations having copied so many management practices from one another over the years is that typically the layers of management methods in place just cause chaos.

One best practice is piled on top of another with little or no thought of the impact on the organization as a whole.

You can stop focusing on costs.

Note the emphasis on reducing cost overall, which may mean increasing costs somewhere else in the system. At least temporarily.

Might it be smarter to pay more to a supplier who provides a product or service that helps the entire organization run more smoothly? Thus, we can reduce costs throughout the organization. In contrast, a lower cost supplier might not mesh so well with your processes and systems.

I encourage you to shift your attention from “actions” taken separately to the interactions within our organization.

Instead, you want to focus on the causes of costs. When we focused on cost cutting, we can cause many negative unintended consequences.

By focusing on cutting costs, we cause people to take short-term actions to reduce costs, such as to reduce maintenance, reduce training, reduce or and reduce innovation, reduce interactions with customers, etc.

We have to begin asking “why are the costs so high?” What are the inputs (the causes) of those costs?

You can stop conducting performance appraisals.

Replace these appraisals with conversations focusing on improving the processes that people use to perform their work.

Instead of an annual performance appraisal. Have an annual conversation that engages supervisors, direct reports and discussions of opportunities for learning in the year ahead, possible career advancements, and alignment of individual and organizational needs.

Again, 94% of the results of any process or system are the result of the process in the system in which people work. In other words, they are from common causes that belong to the system. This is the responsibility of management; not the result of people alone. In other words;

About 94% of the time you want to focus on the inputs, throughputs and outputs of your processes and systems, not on placing blame. This is a big shift in thinking (one you will profit from).

These are just a few things to get you started.

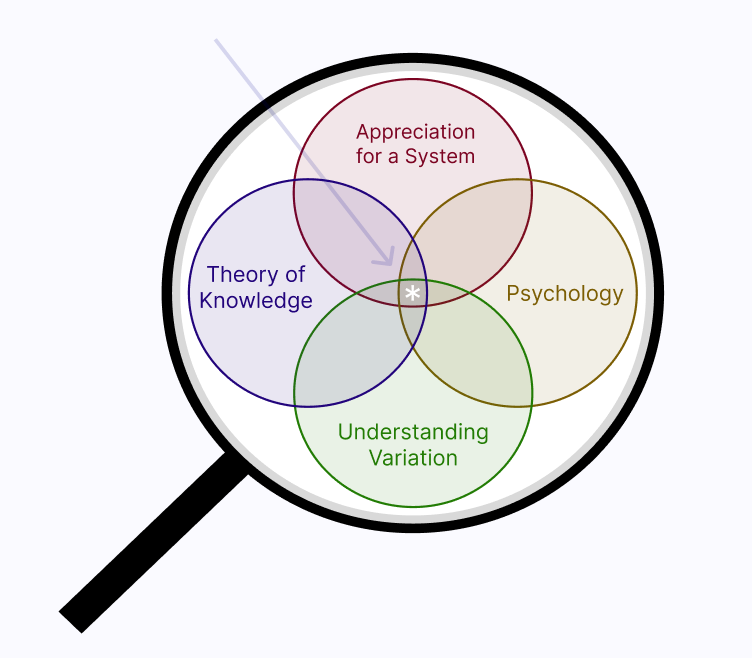

It is important NOT to cherry pick and carelessly apply ideas, principles or techniques from the System of Profound Knowledge (lens).

Instead, we encourage continual learning or the principles. Such learning will keep you from being paralyzed or overwhelmed by Deming’s teachings, and give you the confidence to take the next step, and the step after that – and the step after that…

The System Of Profound Knowledge® (SoPK) is the culmination of W. Edwards Deming’s lifelong work. The SoPK ties together Dr. Deming’s seminal theories and teachings on quality, management and leadership into four interrelated areas: appreciation for a system, knowledge of variation, theory of knowledge and psychology: