Warning: I am challenging your assumptions. These concepts may haunt you the rest of your life.

Before you proceed:

Print, Save or Share this pdf: Deming’s 14 points

I don’t know about you. But,

If you were stranded on a desert island with only one (business) book to read, I advise The New Economics, A Manifesto. Let me ask you this:

Why do Americans identify more with the Simpsons, than the Jetsons?

V

In the late 40’s – early 60’s, America was doing well. The Jetson’s portrayed our projected future.

What changed?

Are you familiar with Dr. W. Edwards Deming?

Let me take a wild guess:

No

(The Great American Tragedy)

Deming built our world

He is the Father of Optimization

Consider recent U.S. History:

Deming, with his knowledge of Statistical Process Control (SPC), transformed America out of the Great Depression into the greatest economic, military, and industrial superpower the world has ever seen (WWII).

After the war, we were the only supplier of goods left standing in world Desperate to rebuild.

As the “skilled labor” (men) returned to work, bringing their military management with them, Is it ridiculous to think we got lazy? Could white man have mistaken his savvy business acumen for the bull market?

Drucker, Welch, Jenson & Meckling and the critical mass, ignored everything Deming taught us.

After WWII,

What did the Japanese ask for?

Steel? Concrete? Fossil fuels? Guess again

That’s right! Dr. Deming.

Deming took this small island with no natural resources where it was illegal to fire employees, from near total ruin, to the world’s second-largest economy within a generation. Historians call this the Japanese Economic Miracle.

Did we (Americans) see this coming? Immediately, we and the rest of world began screaming for protection (tariffs). Why?

Because our Japanese counterparts were producing Superior goods, at a profit, selling them half way across the world to us, at Half price, of what could produce in comparable goods.

Fast forward 50 years. It kind of makes you wonder who really won the war?

As for Continual Improvement:

We don’t even have a word for it.

The Japanese do. They call it Kaizen. It translates to Good, Change.

The irony: This foreign idea is 100% American born and bred.

Yet, today we largely resist knowledge and fear change.

How do you transform a business into a preeminent World-Class powerhouse?

As Michael Crichton says in his book Rising Sun;

“You know how the Japanese can make things this way and we cannot? They Kaizen them. A process of deliberate, patient, continual refinements. Each year their products get a little better, a little smaller, a little cheaper. Americans don’t think that way. Americans are always looking for the quantum leap, the big advance forward. Americans try to hit a home run. They want to knock it out of the park, then sit back. The Japanese just hit singles all day long and they never sit back. So, with something like this. You’re looking at an expression of philosophy as much as anything.”

(Did you know a 1% improvement every day yields 3678% improvement after 1 year?)

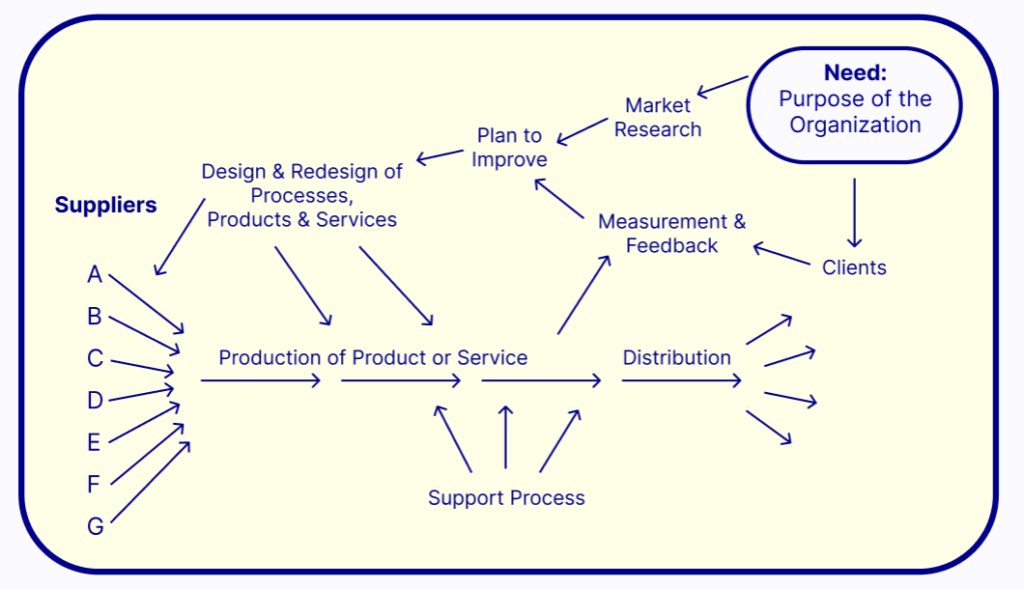

A flow diagram similar to this “was the spark that in 1950 and onward turned Japan around.”

Think about the organization as a system. Drive the concepts of quality at the strategic level. Note how clients are included in the foundation:

Are you scared of the unfamiliar?

Deming was selected as U.S. News and World report as one of the nine (9) hidden turning points of all history.

Much of his contribution is so common that we do not attribute him to it (SPC for example, helped develop COVID-19 vaccines with unprecedented speed, NASCAR, DevOps, Census, etc.)

W. Edwards Deming: Optimization Expert

Greatest statistical thinker in the last 2000 years.

His aim was to bring about a new kind of world.

“The key to unlocking your company’s full potential lies in adopting the Deming philosophy – a proven approach to management that has transformed organizations worldwide.“

Deming’s approach is a way of thinking. It can be applied to anything (family, politics, poverty, inequality, climate and energy problems, government, health care, education, etc. ).

He shared a collection of fundamental truths that show how any system or process can be transformed into something greater.

Please note: There is a wonderful tool used for discovery: Google Deming

It seems impossible to summarize the big idea behind Deming. However, If I were forced to try:

Back in the day, I would have said:

“Raise your Baseline, Lower your Variance“

Yesterday:

Use SPC (Statistical Process Control) AFTER Empowering your Employees

Today:

Map your process, QQC the results. By the M4 method.

(It is eloquently simple)

Focus on Quality (Not by inspection. But from within the process):

Deming had an extraordinary impact in our world. However, it was not until 1980 that he was “discovered” in America: through the White Paper Report (below). This aired in response to our National Crisis: POTUS issue when our former our enemies confined to an island with no natural resources started producing superior products at HALF our cost. Only a couple decades earlier,

Japan and its infrastructure was in total ruin. After WWII, they accepted our help rebuilding: By asking for an unknown statistics professor in New York. Within a few short years, Deming was given credit for the “Japanese economic miracle.” This was “one the hidden turning points in world history.”

My question for you:

If these ideas can transform a country, what can they have on your company?

Unless you want to learn the hard way?

If you know nothing else about Deming, watch this:

Some say this NBC special sparked the American Quality Revolution. It certainly upended how the U.S. and world saw business and industry:

Warning: Some readers may experience this a fascinating, thoughtful, depressing examination of what makes and maintains work ethic. And why we may end up freezing in the dark, and why the Japanese will not:

On a personal note: Within minutes of discovering Deming’s Philosophy I read this and it will haunt me the rest of my life. (I am a Rudolph. Rread Rudolph Factor. Just 10% of your human capital can radically transform your system/ level of innovation:

From page six in his book Out of the Crisis:

What is the world’s most underdeveloped nation? With the storehouse of skills and knowledge contained in its millions of unemployed, and with the even more appalling underuse, misuse, and abuse of skills and knowledge in the army of employed people in all ranks in all industries, the United States may be (still) today the most underdeveloped nation in the world.

“People are entitled to joy in work.”

Most people think there is an overabundance of Joy, Pride, Dignity in our schools, government, health care, corporations and small businesses…

But, the nasty truth is:

Employees cannot even speak honestly with their employers about it: For example

Believe it or not;

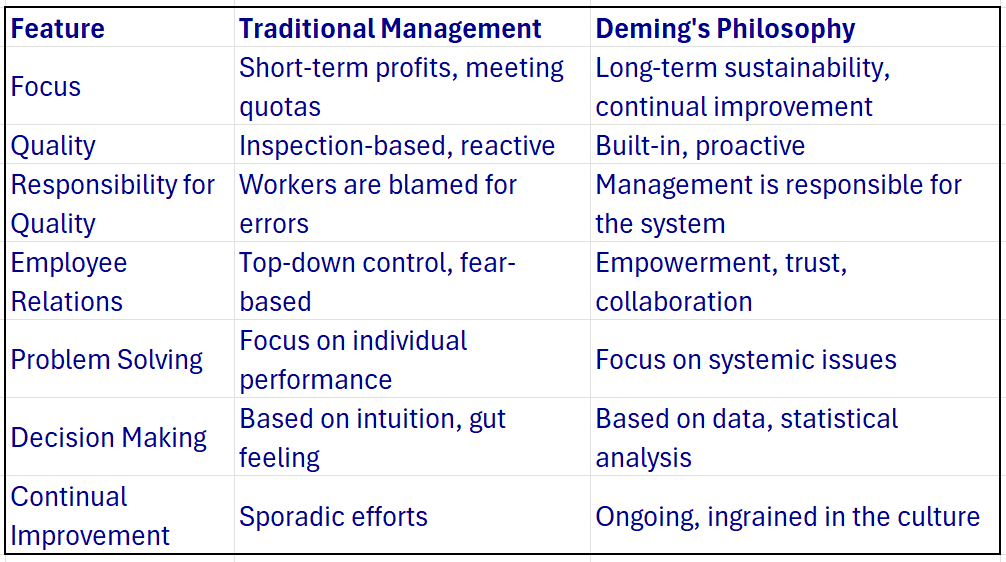

There is a battle for control over management in the western world. The Two opposing world-views:

(Frederick Taylor’s view is leading our world to economic disaster.)

Neo-Taylorism

Frederick W. Taylor assumed that developed systems could be optimal. Experts and managers would instruct workers in all matters.

Based on Newtonian physics; supposing the world around us is deterministic, like a Swiss Clock. Proposing a computable and measurable relation between what is happening presently, and what has happened at any time in the past. A chain of action and reaction that can be projected into the future. An assumption of causal relationships.

Supposedly, the only flaws in this “optimal system” arise from people not understanding, not following procedures, from improper supervision or poor motivation.

Deming

W. Edwards Deming showed that all systems contain flaws, and that by using statistical methods to find and remove these flaws, we can continuously improve our systems.

Based on Quantum Physics, which still baffles many experts. Quantum mechanics tells us that relationships between events may be nonlinear and impossible to predict

The information needed to set up optimal systems is unknown and unknowable.

There are an entirely different categories of flaws that have nothing to do with human performance, even though they are often attributed to workers.

Picture this:

Old School:

Traditional Management:

This company follows traditional top-down management practices. Leaders determine how the work is to be done and give orders to their staff accordingly. Individuals, functional groups and departments are treated as independent entities under centralized control. Pay and promotion are determined Individual performance according to a set of predetermined criteria. Employees are ranked and encouraged to compete with each other.

New School:

Actual Leadership:

Superior companies are managed as an interactive system where people and functional teams depend on each other. Supervisors are not expected to have all the answers. They rely on front line worker’s to share their workplace knowledge and take an active role in improving their work processes. All employees know they are part of a team culture pursuing common goals and solving problems together to move the company forward.

Another way to look at it:

One route enables us to realize the potential of our nation’s enormous energy, brain power and inventiveness.

The other does not.

Taylorism assumes that workers will put forth the least effort possible.

How about, instead, we pretend like humans are an integral part of the process and not a machine part to be swapped out. People can be a wealth of ideas and insight…

We live in a world where management chides, questions, berates, rewards, punishes, warns, stimulates, incites, goads and otherwise tries to motivate people to meet their goals that are often vague and/or impossible to achieve (To be the best, with zero defects).

This nonsense usually starts at age (3) three. In grade school, we begin rating and ranking people, inducing fear, competition and scarcity. Effectively driving out cooperation, creativity, intrinsic motivation, any and all joy in learning.

What is the aim of our schools? Is it to learn? Or, is it to get a good grade? To pass you through to the next grade? If the aim is to learn, why do we not teach HOW TO LEARN? And why the cookie cutter approach? Why the one size fits all approach to learning despite our various learning styles?

Rather than rant – you can study Deming on your own – his approach is so different from what we are used to. In the school example, he insists we abolish the grading system. Why?

Again, the reasons are too numerous to list here. Aside from it being 100% subject (based on opinion, not fact), yet this idea is so striking! The ONLY reason, is because these methods are so ingrained in our consciousness that we don’t even question them. Like an epiphany,

Once you see it, you cannot unsee it. Once you make the connection, you cannot understand why other people “don’t get it.” It is like lifting the blinders that have always shielded you from the truth. For example;

Competition: Why do we promote competition between people and departments working for the same company? Classic example: Paying salespeople commissions. Intuitively we know cooperation is a matter of our survival. Yet we drive it out of school and business like it is the plague? Not yet convinced?

We love to rate and rank. Students get grades. Employee get merit reviews. Test this: Try rating, ranking and performance reviewing your wife and kids and tell me how it works out for you. Why then do we bring these off the wall concepts to work? Idk, but

When working on a project at home, how much smoother is it than doing that same project at work? At home, we have greater control over the system. For example, I want to build a patio. I know the end result. I choose the materials. I decide which tools to use, when, where and how to use them. I don’t have “work arounds” where a manager is ignoring my every “trivial demand.”

I could rattle off 100 examples from my own experience. Multiply this by the millions of employee people throughout the U.S.. This is madness. If you are the business owner and you have no idea what I am talking about – your frustration is a matter of perspective. I got a hunch your interior and exterior realities are no aligned.

You need outside perspective! You will not find innovation anywhere else.

Even though you would rather chop off a finger than implement all 14, here you go:

Deming’s 14-point theory for management: Print this pdf

The characteristic way of management we have been taught in the Western world is to take complex systems, break them into parts, manage each part as well as possible. Problem is,

These “parts” are forced to compete against one another for resources. Everyone suffers.

How many managers are forced to optimize their own department at the expense of the system? How many look after their own career rather than doing what is best for the company overall?

If your company’s aim is long-term productivity gain:

There is no alternative to continually improving your product and service.

(Actual Improvement, not speculation: Systematically testing using scientific methodology, NOT copying other company processes and continuously trying different things on a whim…)

If this makes sense, you have to understand:

The first step in improving your product and service, is by improving the process that creates your product and service. Deming was able to demonstrate:

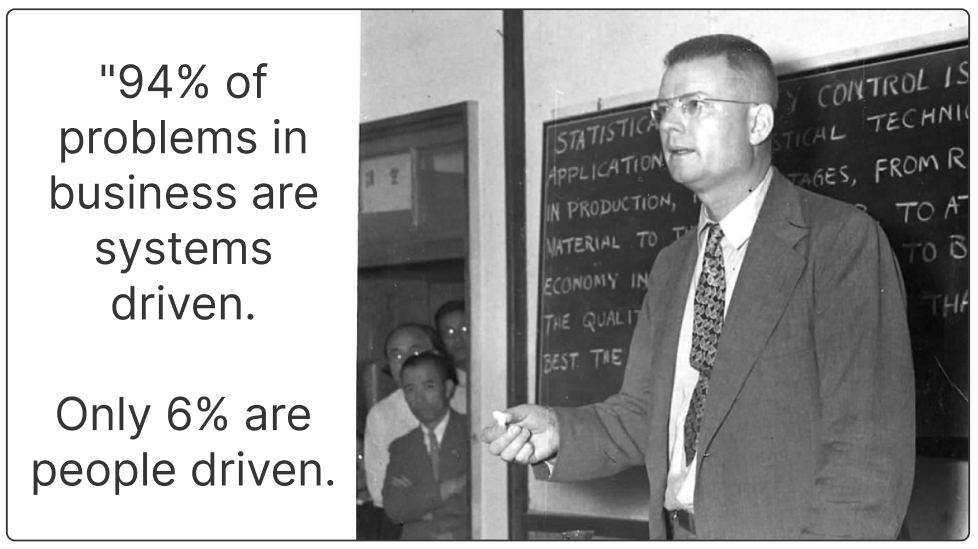

Most troubles and most possibilities for improvement add up to proportions something like this:

- 94% belong to the system (the responsibility of management)

- 6% are attributable to special causes.

(94/6 is commonly accepted. Actual percentages are more extreme – I believe more like 98/2, however I have not yet verified…)

No amount of care or skill in workmanship can overcome fundamental faults of the system.

Yet, how many workers get blamed for management’s ignorance and sloppy thinking?

I heard Apple has employees memorize this:

“I cannot make a mistake. The mistake that occurs is always the result of a system or process my manager has implemented incorrectly.”

Consider the implications…

For over 80 years, the Western ideology of management has dominated the way that you and I think about our businesses. The reality is, it is fundamentally and functionally incorrect. We spend almost all of our time trying to manage people, trying to manage events, trying to psycho-manipulate behaviors. We do not focus on the structure. We do not have a process map that shows us how to get through from point A to point B. We are not having conversations with the seeds (employees) asking what is standing in your way? We are not going to where the seeds have been sown. Instead we are looking at the pests and diseases while ignoring the soil (the people). We are standing on the side saying I planted those seeds six (6) months ago, why haven’t they performed according to these KPIs? I need to tear all those seeds out and throw them away. NO! We have to understand the conditions in which the work is being done, and improve THOSE conditions.

Again, it is has been scientifically proven that 94+% of all problems are the systems by the greatest statistical thinker in the last 2000 years. Now, think about how you and your employers spend their time: When trying to improve your people, you are working on the 6%. Meaning the best you can do is make a small difference… This results in the most insignificant impact (6%). How often do you (or they) work on the systems? Maybe 6% of the time you spend working on the issues that have the largest impact?

“Exactly backwards”

If 94% of all the problems in your business are the result of a system that has been poorly designed, how much of your time are you spending on that? If you are like 90% of the CEOs I know, NONE. You have never spent a moment thinking about the systems. And systems process only comes in two forms: Evolution or mutation. In the void, we need to get things done. Quantity over quality. A focus on output. Or, are you creating processes through intelligent design? With consistent, constant analysis of what is occurring in the system? Designing and implementing new tools, methods, procedures, policies and best practices that resolve recurring issues? Unless you are spending 94% of your time on systems and processes inside your organization, according to the father of process improvement, you are doing it all wrong. How do you solve any problem? Process mapping is a really important part. We have to understand what the process is. Some call for SOPs: Making it easier to train and enforce: This is the old style of management. Once you see it, you cannot unsee it: The system broken. It has a ton of garbage in it. Waste is omnipresent. To top it off, executives have no idea “how the sausage is made.” Their methodology is to sit down with their managers and have them write out what the process is, making this their standard operating procedure. Do you see the fatal flaw with this?

This is the exact opposite of what you should do inside your business. Never documenting anything until you have gone through it with a fine-tooth comb, working with the people in the process, extracting their pain from that, coming up with solutions, resolving those things, creating a more efficient pathway, then and only then do we want to document SOPs, which should be somewhat loose because we should be auditing processes continually, annually at least. It is critical to go back and identify the new problems that have come in. A broken bottleneck creates something else downstream… Focus on the process. Not the people. Most employees have no voice. Are we allowed to voice concerns, choose where to sit, what to wear, when to work…?

94% of all problems are the systems: If you are trying to improve the people, you are working on the 6%. You are working on the thing that is going to have the smallest difference. That is going to make the smallest amount of impact.

How often do you work on the systems?

The “Deadly Diseases” standing in the way of our transformation:

- Lack of constancy of purpose

- Emphasis on short-term profits

- Evaluation of performance, merit ratings, annual reviews

- Mobility of management, job hopping

- Management by the use only of visible figures, with little regard to figures that are unknown or unknowable.

- Excessive medical costs

- Excessive costs of liability, swelled by lawyers who work on contingency fees

Deming suggested every business should have a statistician.

How many do? How many people even know why? What do we do instead?

For a simple and enjoyable way to appreciate the power of statistical analysis, I think of two movies: Moneyball and the Imitation Game.

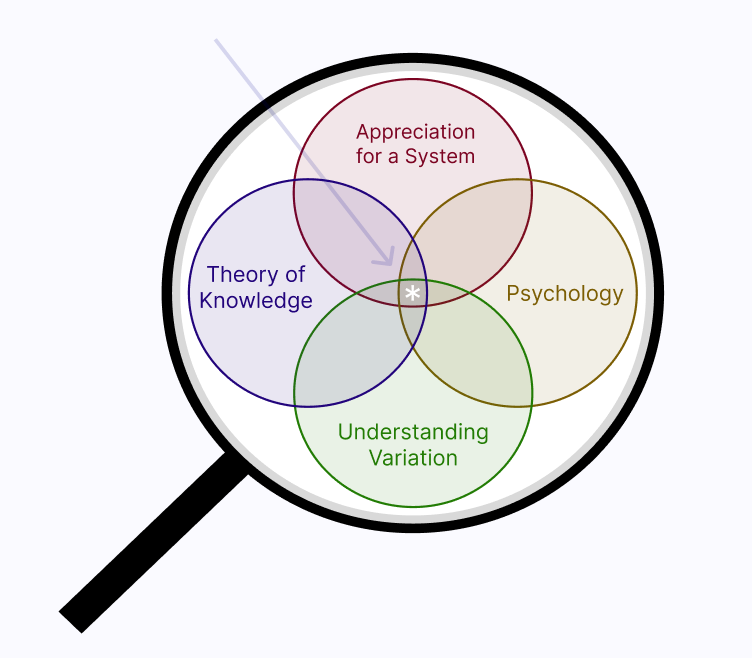

Over Deming’s lifetime he codified a system of systems and named it the System of Profound Knowledge.

If you find this cocky, the more you learn about Ed, the more you realize how humble and soft spoken he was. He gave credit where credit was due. In his books, it seems there is a footnote on nearly every page where he thanks someone for an idea, an insight, or just the inspiration for the topic.

To profoundly change a system, requires know how outside of that system. If the system had that knowledge, it could change itself on its own. This is why managers often bring in high-priced consultants. They know their business has a problem, yet they are too close to the problem to see it. Someone from the outside to step in.

The beauty of the system of profound knowledge is that it provides a way for the owners of a system to bring about their own profound change. No third parties required.

- The theory of knowledge: A theory for knowing how you know something

- The theory of variation: A theory of how to measure what you know

- The theory of psychology: A theory of how to understand human behavior

- Appreciation of system: Systems thinking and an understanding of interconnectedness

To prevent common problems, look at your business through this “lens of profound knowledge,” aka “the science of improvement:”

Get your “Continual Improvement” here:

When it comes to achieve higher quality at lower costs, it helps if you understand Variation and Psychology, if you have an Appreciation for the entire System, and if you know how to continually improve the processes via the Theory of Knowledge.

By using the System of Profound Knowledge you can get closer to the right type of solution faster.

Without the System of Profound Knowledge you are likely to fix either the wrong little thing; and thus miss the big picture aspects of the problem, of you are likely to invest heavily in fixing the entire system when improving a simple little thing is all that was required.

It happens all the time. This can be avoided.

Systems Thinking:

This is a departure from what we have learned since we were children.

Systems thinking is a way of making sense of the complexity of the world, by looking at things in terms of wholes and relationships, rather than by splitting it down into its parts. It has been used as a way of exploring and developing effective action in complex contexts.

Optimize the Whole system, rather than its isolated people/components. Action in one part of the system will have effects in the other parts. This can lead to “unintentional consequences.” The Butterfly effect.

Ignoring the influence of this complexity (the network of interdependent people and components working together to accomplish the aim of the system) helps no one.

Russell Ackoff suggests: “A system is a whole consisting of two or more parts. Each of which can affect the performance or properties of the whole. None of which can have an independent effect on the whole. No subgroup of which can have an independent effect on the whole. In brief; a system is a whole that cannot be divided into independent parts or subgroups of parts.”

We assume every department (individual or work group) is like an independent component. If each person or component functions as intended, according to measured objectives, the company will succeed. This is simply false.

Trying to maximize the individual parts of something reduces the effectiveness of the whole: Image a symphony where every musician is trying to outperform the others…

Psychology:

Helps us better understand people, what motivates them, how they learn, how they interact with your work system.

People are different from one another. To become aware of these differences means you can use them for the optimization of everybody’s abilities and inclinations.

People learn in different ways, and at different speeds. Some learn best by reading, some by listening, others by watching pictures (still or moving) and some by watching someone do it.

Most of our world operates under the supposition that all people are alike; our schools, government, private industry. This is inefficient and detrimental. There is great power in personalization.

Extrinsic motivators rob employees of dignity and self-esteem. If, for higher pay or rating, I do what I know to be wrong, I am robbed of dignity and self-esteem.

To deny employees dignity and self-esteem smothers intrinsic motivation. We are born with a natural inclination to learn and to be innovative.

Psychology helps us to nurture and preserve these positive innate attributes of people.

We get deep fulfillment out of the work we are doing as long as we are allowed to think about it. This does not really happen because our entire management ideology over our entire career suggests that management knows best. (Then why do so many businesses fail?)

Just engaging your people in the process can radically improve it. The free exploring mind of the individual human being is the most valuable thing in the world.

Statistical Variation:

Understanding variation helps us make better decisions. Sometimes it takes 9 minutes to get to the store. Sometimes 10 minutes. Variation is a part of life. Every process varies to some degree. You know this, yet be mindful;

There are two kinds of variation:

- Common Cause (94%): Natural or expected variation in a process.

- Special Cause (6%): Unexpected and outside the system

Warning: Reacting to one as though it were the other is “Tampering.”

Tampering is when you ask for a specific reason why a result is different from a previous result. These false assumptions are a change for the worse. See Funnel Experiment. Hence the expression:

Misidentifying variation is the root of all evil:

Misidentified special cause variation as something that should be predictable (as common cause variation), can lead an organization astray. Applying common cause logic to a special cause situation is equally damaging.

- Mistake One: Reacting to an outcome as if it came from a special cause when it actually came from common causes of variation (overreaction). We see a point (on a behavior/control chart) move in a direction we do not like, or the data point shows performance that is not where we want it, so we react as if it is unique and not like the other data points

- Mistake Two: Treating an outcome as it if came from common causes of variation when in fact it came from a special cause (underreaction). This is a lack of reaction when something unusual is going on, and we assume it is typical and do not learn about it or act on it.

Managers should not waste their time trying to fix every single problem. Instead, they should identify which ones can be predicted, and fix them. Identify the ones that will likely never happen again and do not make knee jerk decisions. As a result, managers can spend their time on things they can control, and waste very little of their time on things they cannot control.

All processes have variation. Patterns of variation can reveal insights into future defects. SPC allows you to statistically predict defects before they occur. According to Statistical Process Control, managers should not waste their time trying to fix every single problem. Instead, they should identify which ones can be predicted and fix them. Identify the ones that will likely never happen again, and avoid the knee-jerk decisions. As a result, managers can spend their time on things they can control and waste very little of their time on things they cannot control.

As Deming said, “A fault in the interpretation of observations, seen everywhere, is to suppose that every event (defect, mistake, accident) is attributable to someone (usually the one nearest at hand), or is related to some special event. The fact is that most troubles with service and production lie in the system. Sometimes the fault is indeed local, attributable to someone on the job or not on the job when they should be. We shall speak of faults of the system as common causes of trouble, and faults from fleeting events as special causes.”

Knowledge:

How do you know what you know is so? As for biases and blind spots, for example:

Let’s suppose we learned how to communicate with dolphins. We would eventually ask, “So, what’s it like to be wet all the time?” The dolphin might wonder what we are talking about. We understand wet because we understand dry. A dolphin would not notice wetness even though it is constantly wet – in fact, because it is constantly wet. Similarly, we are so immersed in our technology, methods and cultural thought processes that trying to evaluate today’s society and business climate from the vantage point of today is inherently difficult. Like any type of self-analysis, it is not surprising that the common perception is off the mark.

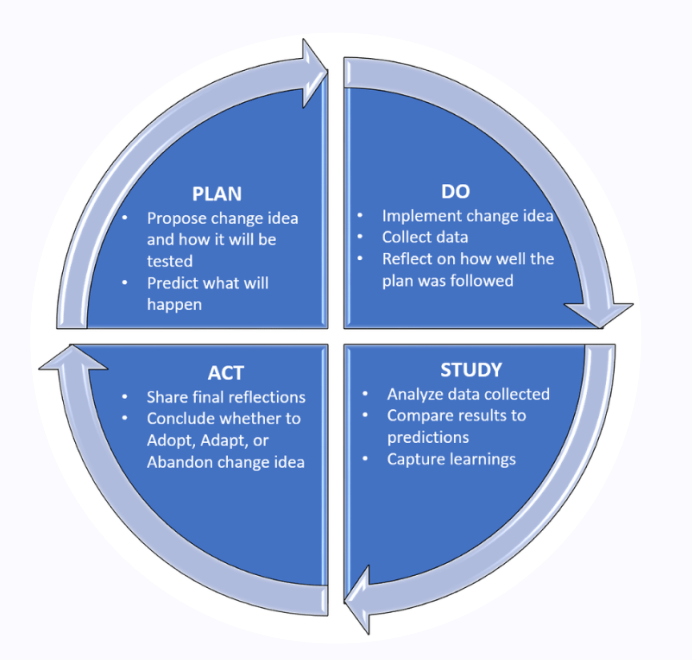

Knowledge is built on theory, prediction and operational definitions. Knowledge is not information, data, nor experience. A science-based tool to help us acquire it: The deceptively simple PDSA:

Creating a never-ending cycle for continual learning and improvement.

Through the PDSA you learn your way to a better system:

A series of weekly or monthly tests, striving toward an intermediate goal. The scientific method. With operational definitions. Developing progression in knowledge. Making it visible. Simple. Mathematically precise. Clear to all.

You are either a learning organization or you are losing to one who is.

The PDSA has become the template to improve virtually every type of system or process:

- First, gather evidence to create a hypothesis. What needs to change?

- Second, make the change.

- Third, review what happened. Is the process better or worse? Why?

- Last, decide where to go from here. Revert to before? Iterate further?

In other words:

Put this on repeat:

Step 1:

Set the goal, direction or challenge

What problem are we trying to solve?

What are we trying to learn?

Where does the organization need to go to remain competitive?

Step 2:

Grasp the current condition:

How do we measure against our challenge?

What is our current way of working?

What do I know (that just ain’t so?)

How do I know it?

What is my threshold of knowledge?

Step 3:

Set the next target condition:

Where am I striving to go next?

What obstacles do I need to overcome to get there?

What will I need to learn.

Step 4:

Experiment to overcome obstacles:

Deliberate learning rather than brainstorming and trying lots of ideas

Each experiment is designed to improve or disprove a hypothesis

PDSA: Try, fail, learn, adjust:

Allowing us to keep advancing our knowledge threshold

Threshold of Knowledge: The point at which you have no facts and data to go on.

There is always a knowledge threshold. To see beyond it, conduct your next experiment.

In my 35 years work experience in a variety of industries, I have never witnessed the scientific approach to acquiring knowledge. What I have seen:

Classic illustration of modern management: Red bead experiment.

Deming was a humanist. He believed:

People are entitled to Joy in Work.

His books were written for people living under the tyranny of the prevailing style of management.

He declared the aim for any organization is for everyone to gain; stockholders, customers, employees, suppliers, community, environment, over the long term.

The ultimate purpose: Continually focusing on improving your products and services.

How else do you set a foundation for excellence?

Transforming a small or mid-size business into a world-class organization, begins with:

- Having a constancy of purpose for long-term productivity gain.

- Plan product and service that will have a market and keep your company in business. Have a common, shared aim. Provide jobs.

- Emphasizing long-term thinking.

- Instead of short-term, investor-led, quarterly pushes to drive financial goals. This is illogical, wasteful, harmful. Not sustainable.

- Instilling the spirit of cooperation.

- Drive out silos, internal competition, merit pay, performance bonus, ratings and grading. Competition is the reason for U.S. decline.

- Driving out fear.

- Stop evaluating performance, merit ratings, annual reviews. They are biased and harmful. Only semi-accurate (with 25 years of data). Understand psychology.

- Avoiding managing with visible numbers only (KPIs, big data).

- Consider the figures that are unknown or unknowable.

- Unleashing intrinsic motivation.

- Remove barriers. Be inclusive instead of exclusive.

- Understanding and define the role of management.

- Adopt the new philosophy.

- Understanding systems thinking and variation, to drive analytical thinking.

- Statistically control to your processes.

- Being proactive instead of reactive.

- Putting out fires leaves you right where you were – at best.

- Developing profound knowledge.

- Take the scientific approach, Plan-Do-Study-Act: PDSA

- Thinking “Win-Win instead of Win-Lose.

- Why increase just your slice? Why not the whole pie? Strengthen your community. Win trust.

- Believing continual improvement is better than “good enough.”

- Why not focus on what went right for a change? Focus on the good and make it better.

The new Mindset:

Cooperation > Competition

Win-win > Win-lose

Inclusive > Exclusive

Systems thinking (to guide analytical thinking)

Continual Improvement > Good enough

Simplicity > Complexity

Results rigid + time flexible

Mentoring > Controlling

Proactive > Reactive

Long-Term > Short-Term

Deming also says that without an aim, there is no system.

In all my years working in a wide ranging of industries, not one company ever had a clear, definitive aim. Think about this.

The list of potential aims is infinite… One person may be striving for client satisfaction. Another just wants to climb the corporate ladder by appeasing the boss. One may be financially driven, by sales, margin or profit.

If you doubt me: Go ask everyone in your organization:

What is the purpose of our business? What is our guiding philosophy? What business are we really in? Why are we trying to do here? What is our core long-term purpose?

My hunch: Everyone has a different answer.

Too many organizations lack a common and shared aim.

Without clear direction, these companies are subject to the soccer metaphor used in:

After polling 23,000 employees, Covey superimposes this metaphor over statistics:

The average organization, if it were a soccer team with 11 people:

- Only (4) four players would know which goal is theirs.

- Only (2) two players would care.

- Only (2) two players would which position they play and know exactly what they are supposed to do.

- All but (2) two players would, in some way, be competing against their own team members.

Why leave direction to chance?

These a just a few superficial highlights. I am certain your business is absolutely amazing, but

Why stop at good? Do you have no sense of better?

Remember, when it comes to the study of the Deming:

We both know: There is no magic formula. No silver bullet. Nothing delivering 100% guaranteed success.

But if you ask me: Deming’s approach comes pretty damn close.

Deming’s contribution most visible in these four nationwide efforts:

- Aberdeen Proving Grounds, when we out manufactured the axis powers during WWII

- Japanese Economic Miracle (their economic recovery after WWII)

- American Quality Revolution of 1980s

- Race to develop and distribute vaccine for Covid 19

The gift Deming gave the world: A way of thinking that can be applied to any facet of life.

A word of warning: If you are new to these concepts, please be advised that nothing I am presenting here is in anyway close to a “how to” guide, nor am I treating these concepts comprehensively. These methods require significant expertise and practice to implement. If you are interested in moving forward, you should expect to engage in an extensive learning journey through books, courses, seminars, mentors, and visits to companies that practice these methods.

Who Was W. Edwards Deming?

W. Edwards Deming was a pioneer in the world of business management and quality improvement. Known for transforming industries in Japan and beyond after World War II, he showed companies how to achieve incredible results by focusing on systems, data-driven decision-making, and empowering employees.

What Makes Deming’s Approach Unique?

Unlike traditional management practices, Deming believed that success comes from improving processes, fostering collaboration, and treating employees as valuable contributors rather than replaceable resources. His philosophy is built on these key ideas:

- Focus on Systems: A business is like an interconnected machine—when you fix the system, the results improve naturally.

- Continuous Improvement: There is always room for better processes, higher quality, and greater efficiency.

- Empower People: Employees thrive when they feel supported, heard, and valued. A strong team creates a stronger business.

- Data-Driven Decisions: Success is not about guesswork; it is about using measurable results to guide change.

How Deming’s Principles Benefit Your Business

Deming’s approach helps businesses achieve:

- Higher Productivity: By streamlining processes and removing inefficiencies, you can get more done with less effort.

- Stronger Teams: Empowered employees are more engaged, motivated, and invested in the business’s success.

- Better Customer Satisfaction: Improved quality and service keep customers coming back.

- Sustainable Growth: Businesses thrive when they operate efficiently and create long-term value.

Why I Follow Deming’s Philosophy

I use Deming’s principles as a foundation for every business I work with because I believe they’re the key to sustainable success. Whether it is improving operations, building trust with employees, or creating a long-term growth plan, his teachings have shown time and again that focusing on systems and people leads to incredible results.

If you have never heard of Deming before, you will quickly see how these ideas can transform the way your business operates—and prepare it for a thriving future.

Begin your journey. Please ask Questions:

If you are curious about how Deming’s principles can apply to your business, or if you would like to explore how I can help implement them please reach out. Our world is starving for this information. Let’s collaborate.

Guiding my Mission: Deming’s Approach to Sustainable Success:

According to the Process Fixer: 48% of businesses fail. 67% of the fastest growing businesses fail. Companies designed to reduce variation (Franchises) fail at just 15%. Real world evidence that Deming’s theories may contain master level savvy?

Everybody and their brother should check out Deming’s books, podcast, YouTube videos and website. The world is starving for the revelations he introduced.

If you are a business owner considering selling your company, or simply exploring how to make your operations smoother and more sustainable, I would love to connect. My goal is to honor what you have built while using proven strategies to take it to the next level.

The First Step:

From the New Economics: A prelude to page “Step 1.”

“The first step in any organization is to draw a flow diagram to show how each component depends on others. Then everyone may understand what his job is. If people do not see the process, they cannot improve it. Anyone needs to see the process as a catwalk, a flow diagram.

In M.B.O. (management by objective), as practiced, the company’s objective is parceled out to the various components or divisions. The usual assumption in practice is that if every component or division accomplishes its share, the whole company will accomplish the objective. This assumption is not in general valid: The components are most always interdependent.

Unfortunately, efforts of the various components do not add up. There is interdependence. Thus, the purchasing people may accomplish a saving of 10 percent over last year, and in doing so raise the costs of manufacture and impair quality. They many take advantage of high-volume discount and thus build up inventory, which will hamper flexibility and responsiveness to meet unforeseen changes in the business.

Peter Drucker was clear on this point, with deep understanding. It is unfortunate that many people do not bother to ready his warning (Management Tasks, Responsibilities, Practices)”